G3 Digital Cutter

Solid reasons for Zünd G3

Production made profitable.

Zünd G3 eliminates the bottlenecks in your finishing department by automating all cutting/trimming functions. Manual cutting, with all inherent costs, potential for mistakes, and lack of efficiency, is reduced to an absolute minimum. With optimized workflow, G3 further boosts productivity.

Versatility and longevity.

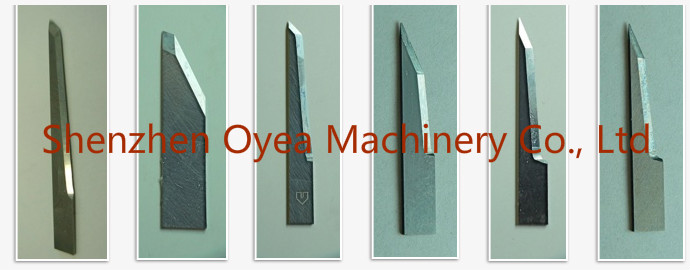

No other cutting or routing machine is as flexible or adaptable as G3 with its modular tool concept. G3 cuts materials up to 50 mm/2” thickness. The selection of sizes, modules, tools, and material-handling options is extensive yet straightforward.

Swiss workmanship, quality, reliability.

G3 cutters from Zünd are specifically designed for 24/7 operation. They offer a unique combination of heavy-duty construction and superb accuracy. The standard 2-year manufacturer`s warranty on the base machine is further evidence of G3`s exceptional quality.

Ergonomics and user-friendliness.

Designed by award-winning industrial designer Richard amiel, G3 provides optimal workflow efficiency with such timesaving features as uninhibited access from all sides, an ergonomically designed control panel, and 60 mm/2,36” clearance between beam and cutting surface.

Safety and eco-friendliness.

With G3, Zünd has made a conscious effort to set new standards in safety and concern for the environment. All G3 safety features are standard equipment. An integrated variable vacuum system keeps both cost and energy consumption to a minimum.

The Best from the Global Market Leader.

G3 is not only a product of celebrated Swiss workmanship but also of Zünd`s 20 years of innovative digital cutter development and 13,000 installations worldwide. With this latest generation, Zünd as global market leader has developed the world`s most advanced cutting/routing system.

For all enquiries and quotations please contact us. We endeavor to reply to you within 12 hours.

Shenzhen Oyea Machinery Co., Ltd.

Add:No. 2008 , Shennan Road , Futian District, Shenzhen

518026, ChinaTel:+86-0769-88014625

Phone Number:+86-18823852826

Email: oyea1688@gmail.com

1659590865@qq.com

Facebook:www.facebook.com/ShenzhenOyea/

Youtube:www.youtube.com/channel/UCG01XsHeFvToKBaAZxEqEcA

Web: www.china-oyea.com

Shenzhen Oyea Machinery Co., Ltd.

Add:No. 2008 , Shennan Road , Futian District, Shenzhen

518026, ChinaTel:+86-0769-88014625

Phone Number:+86-18823852826

Email: oyea1688@gmail.com

1659590865@qq.com

Facebook:www.facebook.com/ShenzhenOyea/

Youtube:www.youtube.com/channel/UCG01XsHeFvToKBaAZxEqEcA

Web: www.china-oyea.com