HSS, which is the abbreviation of high-speed steel, is a standard material for metal cutting tools in the past time. When the tungsten carbide had been created, it was considered to be a direct replacement for HSS with good toughness, excellent wear resistance and extremely high hardness. Cemented carbide is usually compared to HSS, with similar applications and high hardness.

PerformanceTungsten carbide

The cemented carbide is a powder of a micron-magnitude metal carbide, which is hard to melt and has high hardness. The binder is made with cobalt, molybdenum, nickel, etc. It is sintered under high temperature and high pressure. Tungsten carbide has a higher high-temperature carbide content than high-speed steel. It has an HRC of 75-80 and excellent wear resistance.

tungsten carbide strips

Advantages

1. The red hardness of Tungsten carbide can reach 800-1000°C.

2.The cutting speed of cemented carbide is 4-7 times higher than the high-speed steel. Cutting efficiency is high.

3.The mold, measure tools and cutting tools made by tungsten carbide will have 20-150 times higher service life than alloy tool steel.

4.Cemented carbide can cut material with 50 HRC.

Disadvantages

It has low bend strength, poor impact toughness, high brittleness and low shock resistance.

HSS

HSS is high-carbon high alloy steel, which is a tool steel with high hardness, high wear resistance and high thermal resistance. In the quenching state, iron, chromium, partial tungsten and carbon in high speed steel form a extremely hard carbide, Improving the wear resistance of steel. The other partial tungsten is dissolved in the matrix, increasing the red hardness of steel, up to 650°C.

HSS

Advantages

1.Good strength, excellent toughness, sharp cutting edge.

2. Stable quality, generally adopted to make small tools with complex shapes

Disadvantages

The hardness, service life and HRC are much lower than tungsten carbide. At a high temperature of 600°C or above 600°C, the hardness of HSS will decrease significantly, and it can’t be used.

Manufacturing Methods

Tungsten carbide

The manufacturing of cemented carbide is to mix tungsten carbide and cobalt in a certain proportion, pressurize into various shapes, and then semi-sintering. This sintering process is usually carried out in a vacuum furnace. It is placed in a vacuum oven to complete the sintering, and at this time, the temperature is approximately 1300°C and 1,500°C.

tungsten carbide brazed tips

The sintered tungsten carbide forming is to press the powder into a blank and then is heated to a certain degree in the sintering furnace. It needs to keep the temperature for a certain time and then cool down, thereby obtaining the desired carbide material.

HSS

The heat treatment process of HSS is more complicated than cemented carbide, which must be quenched and tempered. During the quenching, due to the poor thermal conductivity, it is generally divided into two stages. Preheat first at 800 ~ 850 °C, so as not to cause large thermal stress, then quickly heat to the quenching temperature 1190°C to 1290 °C which is distinguished when the different grades in the actual use. Then cool down by oil cooling, air cooling or gas-filled cooling.

Applications

Tungsten carbide

Tungsten carbide can also be used as rock-drilling tools, mining tools, drilling tools, measuring tools, carbide wear parts, cylinder liner, precision bearings, nozzles, hardware molds such as wire drawing dies, bolt dies, nut dies, and various fastener dies, which have excellent performance, gradually replacing the previous steel mold.

tungsten carbide wear parts

HSS

HSS has good process performance with a good combination of strength and toughness, therefore mainly used to manufacture metal cutting tools with complex thin edges and good impact-resistant, high-temperature bearings and cold extrusion molds.

Material Ingredients

The cemented carbide has a main component of a metal high hardness refractory carbide with WC, TiC micron powder, cobalt (CO) or nickel (Ni), molybdenum (MO) as the binder. It is the powder metallurgical product sintered in a vacuum furnace or hydrogen reduction furnace.

HSS

High speed steel is complex steel, with a carbon content generally between 0.70% and 1.65%, and 18.91% Tungsten content, a 5.47% Chloroprene rubber content, a 0.11% Manganese content, which is very close to the subsequent W18CR4V component.

Summary

The tungsten carbide tool will be the best choice for most typical metal processing. The cemented carbide has a better performance than HSS, with high cutting speed, long service life and excellent wear resistance. High speed steel is more suitable for tools with complex shapes.

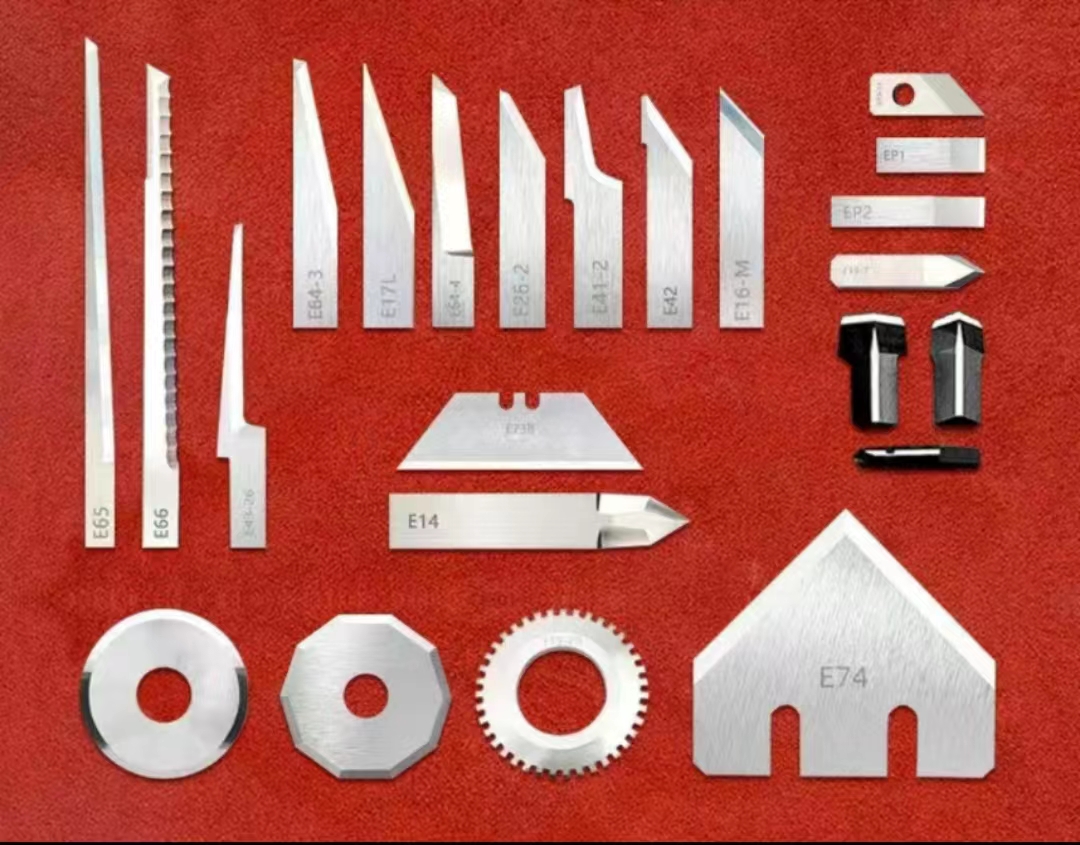

Shenzhen Oyea Machinery Co., Ltd. production Aristo Axyz Atom Benz Blackman & White Bullmer Comagrav CombiPro Data Technology DRD Dierre Dyss Ecocam Elcede Elitron Esko Kongsberg Gerber Graphtec Gunnar Haase iEcho Science & Technology JWei Kasemake Krause Kuris RuiZhou Ronchini Lasercomb Protek Marbach Mécanuméric Mimaki Misomex Multicam RolandSei Summa Valiani Wild Zünd...Tungsten Steel Blades

没有评论:

发表评论